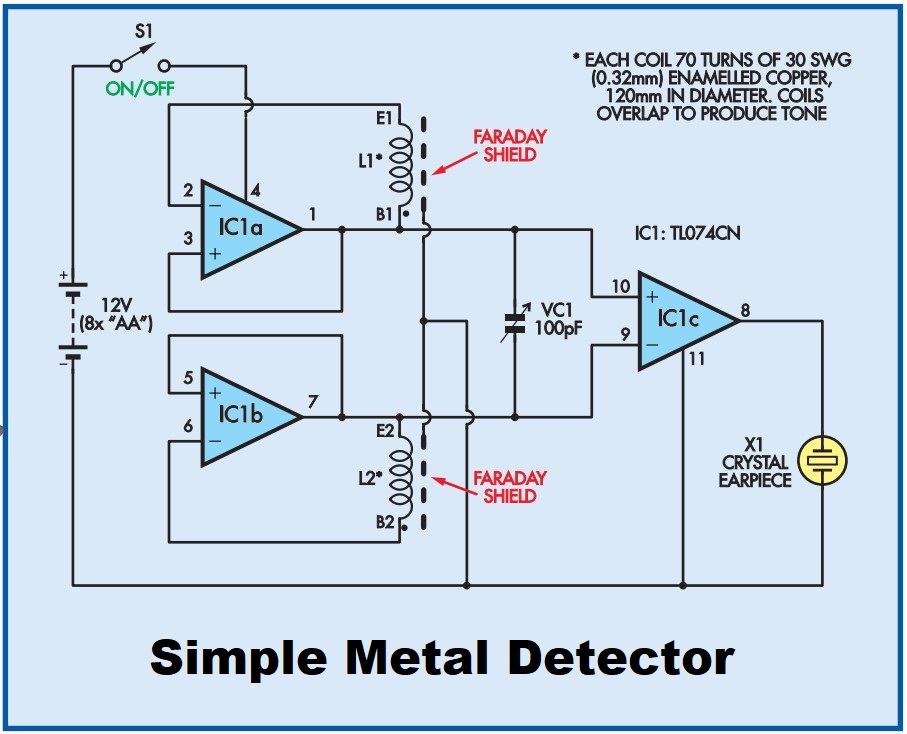

Extremely simple Metal Detector whose making requires only one cheap integrated circuit TL084.

This time I will introduce you to another extremely simple Metal Detector whose making requires only one cheap integrated circuit. The project was presented in Everyday Practical Electronics Magazine by Thomas Scarborough in June 2006. At the expense of simplicity, the results are incredibly good.

The device is characterized by excellent stability and sensitivity, so for example a small metal coin can be detected at a distance of 15 cm, and a larger metal object at more than 50 cm.

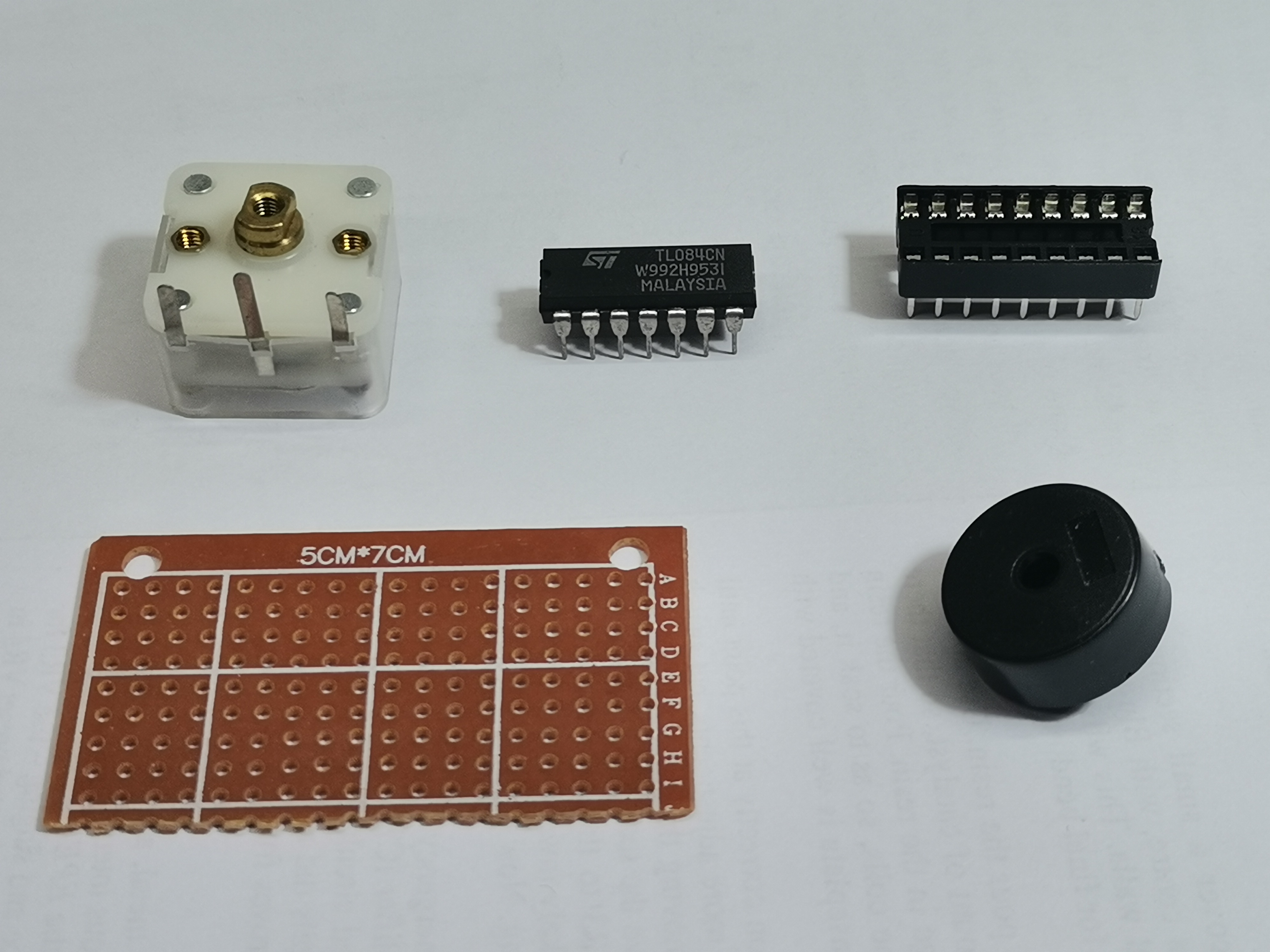

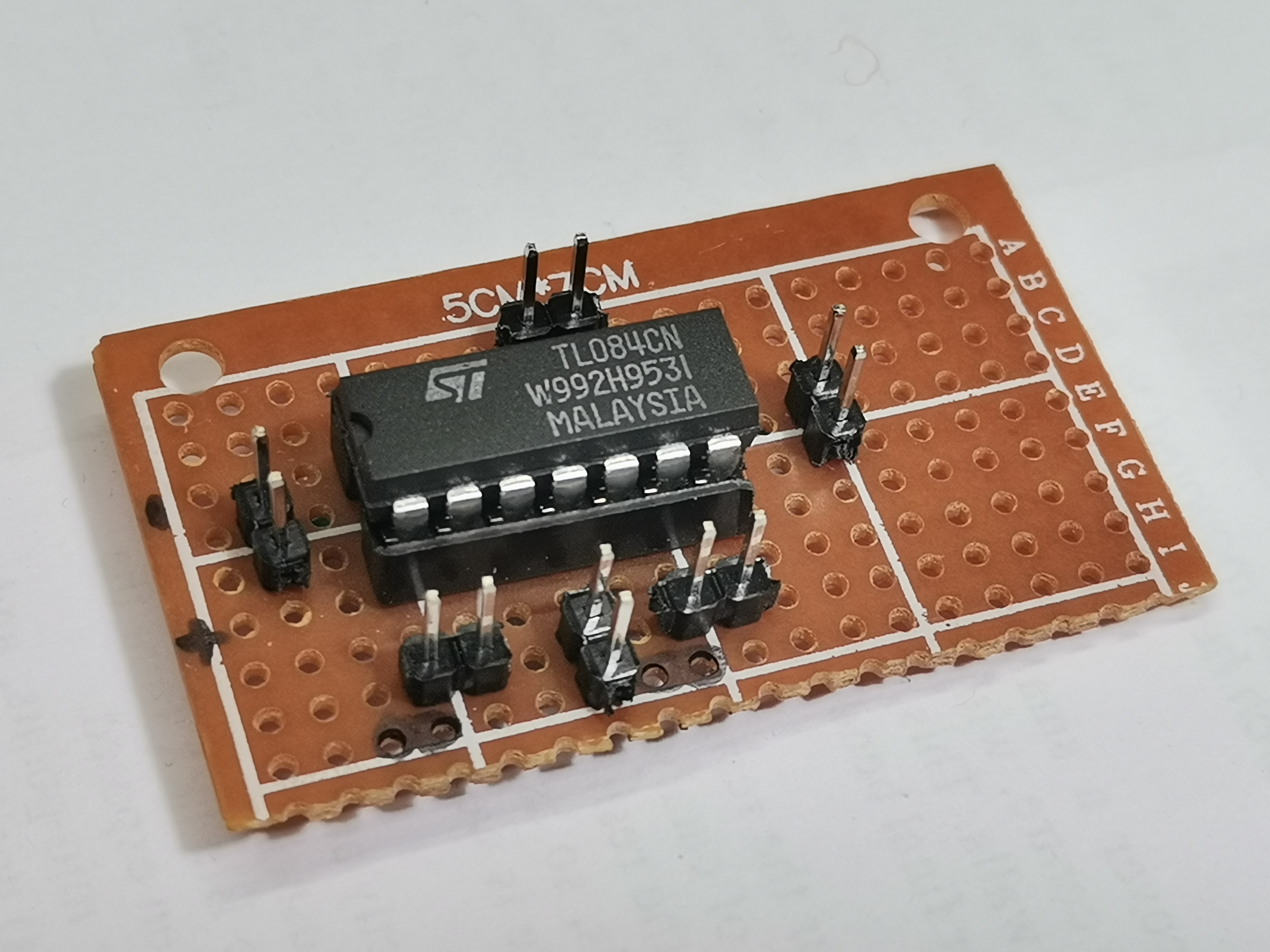

As I mentioned before, the device is very simple to make and contains only a few components:

- TL084 general purpose quad operational amplifier (You can also use TL074 or TL064)

- Small variable capacitor with capacitance of 100pF taken from old portable AM Radio

- Crystal earpiece who need to connect to this jack

- and search coils

The concept borrows caharacteristics of BFO (beat frequency oscillator), and IB (induction balance) principle, so this can be called a BB (beat balance) metal detector. The main characteristics of beat balance (BB) are as follows:

- Depending on the way it is designed, a BB metal locator potentially offers the same sensitivity as IB

- It requires no receiver amplifier or level detector, thus significantly simplifying design and reducing cost.

- Both search oscillators are identical, therefore BB offers high immunity to voltage and temperature variations.

- Each search coil has the opposite response to metal, thus BB has a high degree of immunity to ground mineralisation.

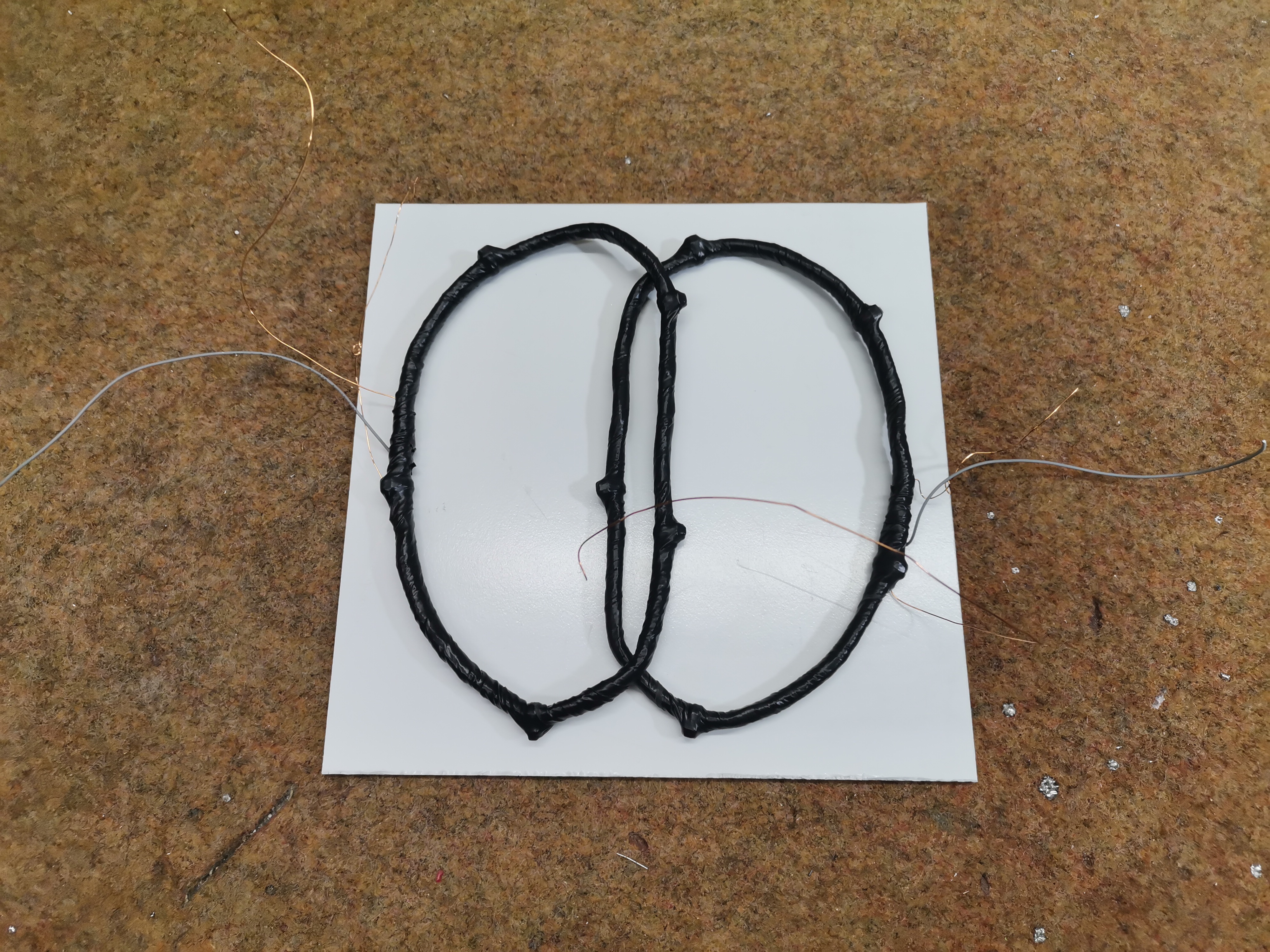

The two coils should be identical and the method of making is as follows:

Each coil has a diameter of 12cm, and consist 70 turns of 30 SWG (0.32mm) enamelled copper wire. Then the coils are folded in the shape of the letter D, wrapped tape around them, screened them using aluminium foil bound with tinned copper wire (taking care to leave a small gap so that the screen doesn’t behave like a shorted turn), and tie-wrapped them on to a plastic plate. Next we need to attach the coils to the circuit by means of the specified microphone cables, being careful to identify the beginning and end wires correctly as shown.

Setting up the Metal Detector is very simple:

- First we need to place the two windings so that the gap between them is the smallest and the variable capacitor is in the middle position.

- A very high frequency tone is now heard on the handset.

- Next we need to gradually increase the overlap, reducing the frequency of the sound in the handset.

- So we continue until the moment when the sound is lost.

- Then we move the variable capacitor to the moment when a sound with the lowest frequency is heard.

- Now the detector is the most sensitive.

- The detector works surprisingly stable, but from time to time it needs to be precisely adjusted with the variable capacitor.

For a clearer presentation, I connected the headphone output to an audio amplifier, otherwise the headphone volume is quite sufficient for outdoor work. In the video, you can follow the sensitivity of this detector in the air. On the ground, the situation is completely different and depends on its composition and humidity.